Permanent Magnet Alternators: Efficient, Reliable Power Solutions

Permanent magnet alternators have been widely used in many fields due to their excellent performance, providing reliable power support for the development of various industries and becoming a key force in promoting industrial progress.

Renewable energy field

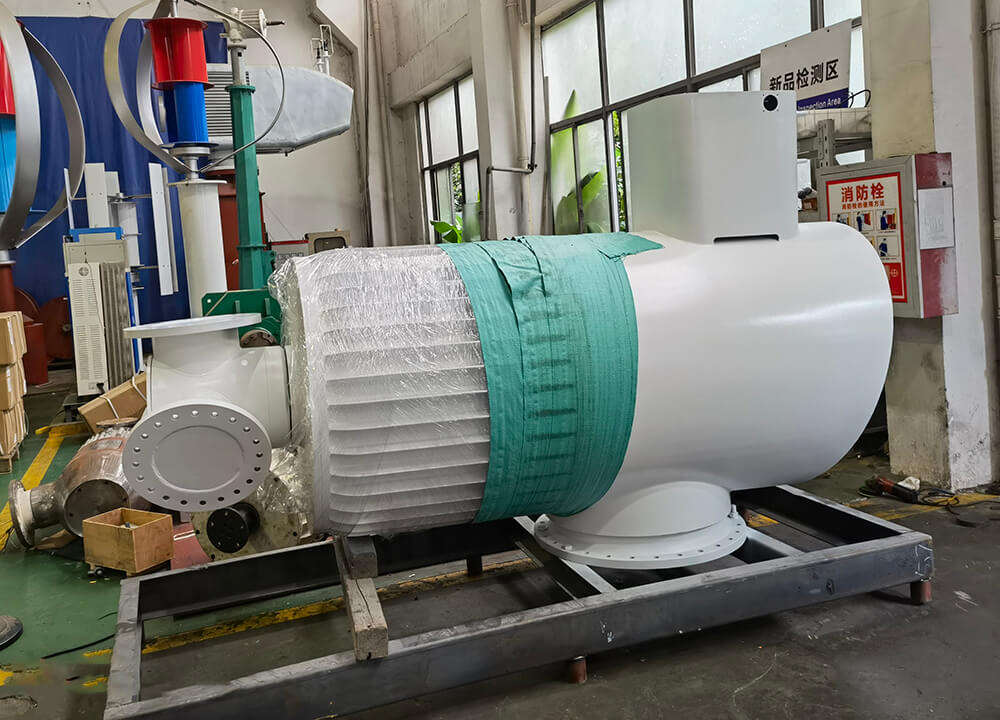

In wind power generation, permanent magnet direct-drive wind turbines occupy an important position. It can be directly connected to the wind wheel without the need for a gearbox, reducing energy loss and mechanical failure, and improving power generation efficiency and stability. With the continuous development of wind power generation technology, the single-unit capacity of permanent magnet wind turbines has continued to increase, from hundreds of kilowatts in the early days to several megawatts today, becoming the preferred equipment for large wind farms.

In the field of solar power generation, permanent magnet alternators are often used in conjunction with solar panels to convert solar energy into electrical energy for storage and utilization. It can adapt to the intermittent and volatile nature of solar power generation, ensure the stable output of electricity, and provide reliable protection for off-grid and grid-connected solar power generation systems.

In small hydropower stations, permanent magnet alternators also perform well. It can adapt to different head and flow conditions and efficiently convert water energy into electrical energy. Due to its simple structure and easy maintenance, it is very suitable for use in small hydropower stations in remote areas, providing a stable power supply for local residents.

Industry and Manufacturing

In industrial production, permanent magnet alternators provide stable power for various industrial equipment to ensure the continuity and stability of production.

In the steel, chemical, textile and other industries, many large-scale mechanical equipment require strong and stable power support. Permanent magnet generators can meet the needs of these equipment, and their high efficiency and energy-saving characteristics can also help enterprises reduce production costs and improve production efficiency.

For example, in automated production lines, permanent magnet alternators provide power for robots, automated equipment, etc., to ensure the precise operation of production lines, improve product quality and production efficiency.

In mining, permanent magnet alternators are used to drive ventilators, hoists and other equipment to provide security for the safe production of mines. Its high reliability and stability can continuously operate in harsh working environments, reducing equipment failures and downtime.