Manual de Manutenção Rotineira para Turbina Eólica

I. Cronograma de Manutenção

Unidades Novamente Comissionadas: Realize a primeira manutenção rotineira após 500 horas de operação (aproximadamente um mês).

Unidades em Operação: Realize manutenção rotineira a cada 5000 horas ou uma vez por ano.

II. Manutenção da Pá

Tratamento de Rachaduras e Danos

- Se as rachaduras se estenderem até a camada reforçada de fibra de vidro, a reparação é obrigatória.

- Se a carenagem da pá estiver danificada, notifique o fabricante para reparo.

- Reparos podem ser realizados no local quando a temperatura ambiente for ≥10℃. Se inferior, adie os reparos.

- Não opere o aerogerador até que o adesivo esteja completamente curado após o reparo.

- Inspecione a integridade do cabeamento de proteção contra raios, sem interrupções ou conexões frouxas.

- Verifique sinais de golpe de raio (marcas de queimaduras, rachaduras, barulho de clique).

Inspeção do Parafuso da Lâmina

- Verifique se todos os parafusos de instalação da lâmina atendem ao torque especificado.

- Inspecione os parafusos quanto a ferrugem ou danos; substitua se necessário.

III. Manutenção do Sistema Elétrico

- Verifique se o feedback de dados de cada sensor está normal.

- Verifique e aperte os terminais dos cabos para evitar conexões falsas e folgas.

- Use um teste de isolamento para testar o circuito principal e garantir que o valor de isolamento esteja dentro da faixa normal.

- Verifique a aparência do cabo e do polo de saída do gerador quanto a envelhecimento e ruptura.

- Verifique os principais componentes elétricos e módulos plugáveis para confirmar que sua aparência não está queimada e que a conexão é firme.

- Verifique se os botões e displays do painel de controle respondem e exibem normalmente.

- Verifique o selamento do painel de controle para garantir proteção contra poeira e umidade.

- Verifique o sistema de proteção contra raios e o dispositivo de aterramento, medindo se a resistência de aterramento atende aos requisitos e verificando a confiabilidade da conexão.

IV. Manutenção do Sistema Mecânico

- Verifique o torque de todos os parafusos críticos para garantir a fixação.

- Inspecione a lubrificação em todos os pontos de lubrificação.

- Inspecione as soldas da torre, as conexões de flange e os equipamentos auxiliares.

- Verifique se a folga das pastilhas de freio atende aos requisitos e ajuste-as a tempo, se necessário.

- Verifique a proteção contra corrosão geral e mantenha-a, se necessário.

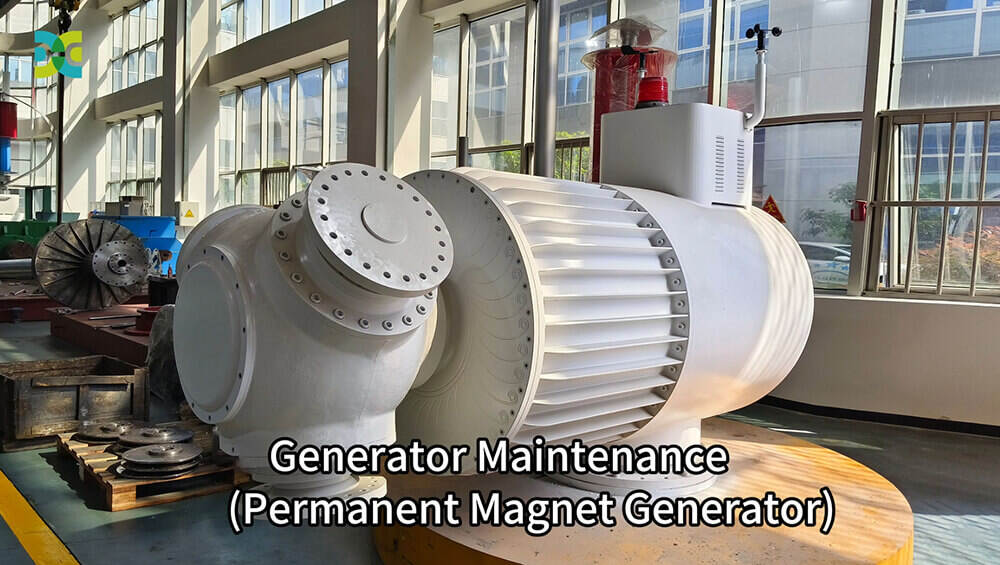

V. Manutenção do Gerador (Gerador de Imã Permanente)

- Medir a resistência da isolamento do enrolamento do estator para garantir a segurança.

- Inspecionar os polos do rotor quanto à desmagnetização, danos ou corrosão.

- Verificar o funcionamento dos rolamentos em busca de ruídos anormais ou superaquecimento.

- Verificar a carcaça do gerador e os fixadores quanto a folgas.

- Para rolamentos lubrificados, verificar se a graxa é suficiente e limpa.